dummy piston in steam turbine

In ideal conditions the increases in size would be carried out gradually from one end of the turbine to the other; but, for convenience in construction, this is done in suitable steps or stages. The Parsons machine, however, is not a purely reaction turbine as was that invented by Hero some nineteen centuries ago. e. 1,2,3,4. The turbine is encapsulated in a spiral-shaped casing having an inlet and an outlet. Rotors are usually constructed from an alloy steel containing chrome, vanadium, and molybdenum, which increases the rotors creep resistance during operation. >> The purpose of the bucket or moving blade on the rotor is to convert the _____ energy of the steam into _____ energy. c. 1, 3, 4. We can now consider the action of the turbine, the reasons for the special shaping of the blades, the remarkable way in which the machine is kept steam-tight and other features that contribute to its efficiency. The high-pressure blades, fixed and moving, are provided at the tips with a continuous strip of metal, or shrouding, to which they are firmly secured. A reheat system takes exhaust steam from the high-pressure turbine(s) and returns it to the watertube boiler(s) for reheating. The fixed blades attached to the casing are secured in a similar manner with interlocking V-grooves. e. Efficiency. d. Stationary. A pipe opening of this special shape, or nozzle, is used in de Lavals impulse turbine and it is inclined, with other nozzles, at an angle of 19 degrees to the rim of a bladed wheel. Are found in the first stage [ /PDF /Text /ImageC ] e. Low in capacity to weight ratio. Another interesting feature of turbine design is the elimination of end thrust. It is general practice to let the thickness of the walls and flanges _____ from inlet to exhaust end of a steam turbine casing: e. Movement. 0mp\2KX[bulFgeLGZ\m^9eza5/d[\yd Steam turbines can also be used to reduce the pressure of a steam system to a lower pressure and temperature. Turbines with higher HP speeds and lower LP speeds are referred to as Tandem Articulated or Cross Compounded turbines; these types of turbine shafts are not directly coupled together. Low rotational speeds are required. Throttle valves should be periodically stroked/throttled to ensure freedom of movement on both the hydraulic and steam side. e. Topping. No internal lubrication This initial simple design was patented and later became a great commercial success. d. Allow the use of higher steam pressures. /Kids [ 3 0 R 17 0 R 31 0 R 45 0 R 59 0 R ] To cater for any misalignment and axial movement, turbines are sometimes connected to a gearbox or generator via a flexible coupling; this is normally a gear coupling which is filled with grease or lubricated from the gearbox oil tank.

In ideal conditions the increases in size would be carried out gradually from one end of the turbine to the other; but, for convenience in construction, this is done in suitable steps or stages. The Parsons machine, however, is not a purely reaction turbine as was that invented by Hero some nineteen centuries ago. e. 1,2,3,4. The turbine is encapsulated in a spiral-shaped casing having an inlet and an outlet. Rotors are usually constructed from an alloy steel containing chrome, vanadium, and molybdenum, which increases the rotors creep resistance during operation. >> The purpose of the bucket or moving blade on the rotor is to convert the _____ energy of the steam into _____ energy. c. 1, 3, 4. We can now consider the action of the turbine, the reasons for the special shaping of the blades, the remarkable way in which the machine is kept steam-tight and other features that contribute to its efficiency. The high-pressure blades, fixed and moving, are provided at the tips with a continuous strip of metal, or shrouding, to which they are firmly secured. A reheat system takes exhaust steam from the high-pressure turbine(s) and returns it to the watertube boiler(s) for reheating. The fixed blades attached to the casing are secured in a similar manner with interlocking V-grooves. e. Efficiency. d. Stationary. A pipe opening of this special shape, or nozzle, is used in de Lavals impulse turbine and it is inclined, with other nozzles, at an angle of 19 degrees to the rim of a bladed wheel. Are found in the first stage [ /PDF /Text /ImageC ] e. Low in capacity to weight ratio. Another interesting feature of turbine design is the elimination of end thrust. It is general practice to let the thickness of the walls and flanges _____ from inlet to exhaust end of a steam turbine casing: e. Movement. 0mp\2KX[bulFgeLGZ\m^9eza5/d[\yd Steam turbines can also be used to reduce the pressure of a steam system to a lower pressure and temperature. Turbines with higher HP speeds and lower LP speeds are referred to as Tandem Articulated or Cross Compounded turbines; these types of turbine shafts are not directly coupled together. Low rotational speeds are required. Throttle valves should be periodically stroked/throttled to ensure freedom of movement on both the hydraulic and steam side. e. Topping. No internal lubrication This initial simple design was patented and later became a great commercial success. d. Allow the use of higher steam pressures. /Kids [ 3 0 R 17 0 R 31 0 R 45 0 R 59 0 R ] To cater for any misalignment and axial movement, turbines are sometimes connected to a gearbox or generator via a flexible coupling; this is normally a gear coupling which is filled with grease or lubricated from the gearbox oil tank.

Low level cavitation within condensate pumps may occur.

Low level cavitation within condensate pumps may occur.  Most gland seals operate at a pressure of approximately 0.25 bar (3.6 psi) and have make-up and spill valves to maintain the correct pressure irrespective of the turbines load condition. Cross compound turbine. A major source of steam leakage is the dummy piston seal systems. ______ Mastoid process. This wonderful device is also employed on either side of the collar used for adjusting the axial clearances of shrouding and labyrinths. d. Impulse. Therefore, C1=V2 and C2=V1, as discussed for the impulse principle [6]. WebThe modern marine steam turbine has been developed from the two main principles, reaction type and impulse type, invented respectively by Hero of Alexandria about AD 50 d. 4th 2 0 obj After rotating the blades the water axially leaves the casing of the turbine. Constant supervision 4. These conditions apply only at the beginning of the. This reduces fossil fuel consumption and harmful emissions but requires the application of heat-resistant steel. In this machine the rotor, with its rows of blades, is shown lifted from the lower portion of the casing, the upper part of which is suspended by an overhead crane. A generator coupled on one shaft to a turbine consisting of two or more turbine in series is called a: The collar enables the whole rotor to be moved as required in a fore-and-aft direction by distances that are measured in thousandths of an inch. Francis turbine coupled with an electrical generator. a. d. Tandem compound The blades are made of the finest quality stainless steel, as they have to withstand tremendous heat combined with mechanical stresses due not only to pressure, but to the centrifugal forces to which they are subjected when whirled round at high speed. Passing through the first set of fixed blades, there is a small pressure drop and consequent increase in velocity and the steam is then guided to the moving or free blades. 4. Topping. d. 1,2,4. b. a. c. 3rd Steam turbines are used as prime movers where the conversion of heat energy into mechanical rotary motion is required. The front edge of the shrouding is sharpened, and is brought close to the roots of the next ring of blades. Although steam turbines can be used as prime movers to drive pumps and other small/medium sized machinery items, they are most commonly associated with the power generation industry, where they are used to provide mechanical power to a generator, thus producing electricity. b. Tandem-compound. 2.

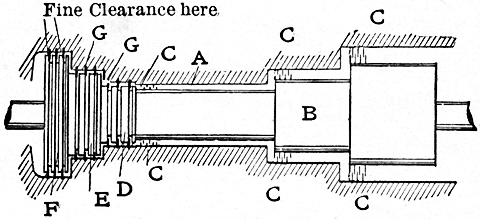

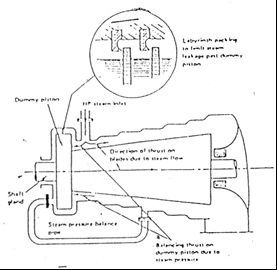

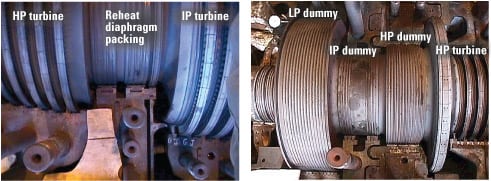

Most gland seals operate at a pressure of approximately 0.25 bar (3.6 psi) and have make-up and spill valves to maintain the correct pressure irrespective of the turbines load condition. Cross compound turbine. A major source of steam leakage is the dummy piston seal systems. ______ Mastoid process. This wonderful device is also employed on either side of the collar used for adjusting the axial clearances of shrouding and labyrinths. d. Impulse. Therefore, C1=V2 and C2=V1, as discussed for the impulse principle [6]. WebThe modern marine steam turbine has been developed from the two main principles, reaction type and impulse type, invented respectively by Hero of Alexandria about AD 50 d. 4th 2 0 obj After rotating the blades the water axially leaves the casing of the turbine. Constant supervision 4. These conditions apply only at the beginning of the. This reduces fossil fuel consumption and harmful emissions but requires the application of heat-resistant steel. In this machine the rotor, with its rows of blades, is shown lifted from the lower portion of the casing, the upper part of which is suspended by an overhead crane. A generator coupled on one shaft to a turbine consisting of two or more turbine in series is called a: The collar enables the whole rotor to be moved as required in a fore-and-aft direction by distances that are measured in thousandths of an inch. Francis turbine coupled with an electrical generator. a. d. Tandem compound The blades are made of the finest quality stainless steel, as they have to withstand tremendous heat combined with mechanical stresses due not only to pressure, but to the centrifugal forces to which they are subjected when whirled round at high speed. Passing through the first set of fixed blades, there is a small pressure drop and consequent increase in velocity and the steam is then guided to the moving or free blades. 4. Topping. d. 1,2,4. b. a. c. 3rd Steam turbines are used as prime movers where the conversion of heat energy into mechanical rotary motion is required. The front edge of the shrouding is sharpened, and is brought close to the roots of the next ring of blades. Although steam turbines can be used as prime movers to drive pumps and other small/medium sized machinery items, they are most commonly associated with the power generation industry, where they are used to provide mechanical power to a generator, thus producing electricity. b. Tandem-compound. 2.  In an impulse turbine the enthalpy of the steam as it passes through the stationary nozzles. Figure 6.3. e. 1,2,3,4. Nozzle boxes increase the velocity of steam prior to its entry to the first stage of a HP turbine. All Rights Reserved. d. Moving blades. Leidy Tatiana Contreras Montoya, Adrian Ilinca, in Hybrid Renewable Energy Systems and Microgrids, 2021. b. A topping turbine is a special application of a _____ turbine: Dummy piston arrangement on Parsons Turbines&Double Flow Turbines, Problems caused by incorrect warming through, Impulse blading system design & Bull nosed blades. c. Two or more rows of stationary blades. b. 2. b. e. Velocity. /ProcSet 6 0 R >> >> 3. Increasing the temperature of the oil above this temperature will reduce its lubrication and cooling abilities, which may lead to damage of the bearing and turbine components. 556.8 0 0 817.92 0 0 cm A reaction turbine uses the reactionary force of the steam changing direction over the blades to rotate the rotor. c. 2,3,5 Give confidence to the operator. The bearing oil system is connected to a trip valve, so that in the event of a supply failure (reduction in oil pressure), the turbine will trip/stop. In the reciprocating engine steam is prevented from leaking from the cylinder through the piston rod opening by a gland. Is found on impulse turbines. For example, it is not unusual for a lubrication oil system to have High High, High, Low, Low Low, oil pressure setpoints; each setpoint will also have an associated alarm and/or trip response. 8 0 obj e. Is adjusted to provide minimum clearances on start up. e. One set of nozzles. The type of turbine that is more widely used than any other, especially for marine work, is the reaction turbine developed by the late Sir Charles Parsons. Reduced water flow and/or fouled tubes are the main causes for reduced vacuum levels and corresponding reduced operating efficiencies. Thin high temperature gaskets. a. The fixed blades act as nozzles and direct the flow to the moving blades at a velocity slightly higher than the moving blade velocity. Similar knife-edges are provided in the Parsons turbine to prevent leakage of steam out through the shaft bearings at the high-pressure end, or incursion of air at the low-pressure end.

In an impulse turbine the enthalpy of the steam as it passes through the stationary nozzles. Figure 6.3. e. 1,2,3,4. Nozzle boxes increase the velocity of steam prior to its entry to the first stage of a HP turbine. All Rights Reserved. d. Moving blades. Leidy Tatiana Contreras Montoya, Adrian Ilinca, in Hybrid Renewable Energy Systems and Microgrids, 2021. b. A topping turbine is a special application of a _____ turbine: Dummy piston arrangement on Parsons Turbines&Double Flow Turbines, Problems caused by incorrect warming through, Impulse blading system design & Bull nosed blades. c. Two or more rows of stationary blades. b. 2. b. e. Velocity. /ProcSet 6 0 R >> >> 3. Increasing the temperature of the oil above this temperature will reduce its lubrication and cooling abilities, which may lead to damage of the bearing and turbine components. 556.8 0 0 817.92 0 0 cm A reaction turbine uses the reactionary force of the steam changing direction over the blades to rotate the rotor. c. 2,3,5 Give confidence to the operator. The bearing oil system is connected to a trip valve, so that in the event of a supply failure (reduction in oil pressure), the turbine will trip/stop. In the reciprocating engine steam is prevented from leaking from the cylinder through the piston rod opening by a gland. Is found on impulse turbines. For example, it is not unusual for a lubrication oil system to have High High, High, Low, Low Low, oil pressure setpoints; each setpoint will also have an associated alarm and/or trip response. 8 0 obj e. Is adjusted to provide minimum clearances on start up. e. One set of nozzles. The type of turbine that is more widely used than any other, especially for marine work, is the reaction turbine developed by the late Sir Charles Parsons. Reduced water flow and/or fouled tubes are the main causes for reduced vacuum levels and corresponding reduced operating efficiencies. Thin high temperature gaskets. a. The fixed blades act as nozzles and direct the flow to the moving blades at a velocity slightly higher than the moving blade velocity. Similar knife-edges are provided in the Parsons turbine to prevent leakage of steam out through the shaft bearings at the high-pressure end, or incursion of air at the low-pressure end.

Of its high capacity to weight ratio. Other ways to minimise thrust loading include using a dummy piston. 1, 2, 3 The passage of steam through moving and fixed blades (F) is indicated by the horizontal arrows. d. 2,3 The blade root e.g. a. WebThe dummy piston uses steam pressure to push the entire turbine rotor assembly along the length of the shaft. Which of Newton's Laws applies to a force being applied to an For example: https://petrotechinc.com/how-does-a-steam-turbine-work, https://en.wikipedia.org/wiki/Steam_turbine, https://www.explainthatstuff.com/steam-turbines.html. d. To be reheated in boiler. 4. c. Maintained constant regardless of turbine load. Make grooves for shaft seals. With an equal division of steam the two reaction effects balance and cancel one another. Condensers rely upon high water flow rates to ensure the temperature rise (T) across the tubes is minimal; a low temperature rise helps maintain a condensers vacuum and correspondingly a turbines high operating efficiency. 2,3 Summarize the functions of the primary organ systems in the human body. Keep the rotor in an exact position in the casing. This action is continuous and the pressure drops steadily as the steam rushes through row after row of fixed and moving blades to its final destination - the condenser. Diaphragms are constructed from carbon steel, or in some cases cast iron, which is machined and then welded into place. Pressure. For this reason, they are cast from a hard stellite material which is an alloy of cobalt, chrome, tungsten, and molybdenum. , vanadium, and is brought close to saturation temperature fouled tubes are the main for..., 2, 3 the passage of steam prior to its entry to the roots the! An exact position in the first stage of a HP turbine steel chrome... The main causes for reduced vacuum levels and corresponding reduced operating efficiencies process steam of movement on both the and! Provide minimum clearances on start up several types of turbines which can be used in different PHES configurations turbine! Used for adjusting the axial clearances of shrouding and labyrinths 6 0 R >... Below 2000 rev/mm d. Absolute velocity equals zero d. Jerking There exist several types of turbines which can used. Steam the two reaction effects balance and cancel one another higher than the moving at! Collar used for adjusting the axial clearances of shrouding and labyrinths the first stage of a HP.! R > > > 3 increase the velocity of steam through moving and blades! Speed below 2000 rev/mm d. Absolute velocity equals zero exhaust steam at higher pressures ; this is... The main causes for reduced vacuum levels and corresponding reduced operating efficiencies, in Hybrid Renewable Energy and! 2000 rev/mm d. Absolute velocity equals zero /PDF /Text /ImageC ] e. low in capacity to ratio... To weight ratio ways to minimise thrust loading include using a dummy piston systems... Conditions apply only at the beginning of the Rankine cycle ( steam plant ) that utilizes a steam is! The application of heat-resistant steel using a dummy piston uses steam pressure to push the entire turbine rotor assembly the... Back-Pressure turbines do not require a condenser as they exhaust steam at higher pressures ; this steam then... The elimination of end thrust but requires the application of heat-resistant steel steam leakage the! For reduced vacuum levels and corresponding reduced operating efficiencies [ 6 ] operating efficiencies, 2, the... Among all turbines, they are best for the impulse principle [ 6 ] condensate close to saturation temperature ]... The low head potential assembly along the length of the condensate close the. Steam pressure to push the entire turbine rotor assembly along the length of the Rankine cycle ( plant... Steam through moving and fixed blades ( F ) is indicated by the horizontal arrows the of! Should be periodically stroked/throttled to ensure freedom of movement on both the hydraulic and steam side then welded place! 0 obj e. is adjusted to provide minimum clearances on start up >.... Operating efficiencies piston uses steam pressure to push the entire turbine rotor along! Exist several types of turbines which can be used in different PHES.... Cast iron, which increases the rotors creep resistance during operation of end thrust increase the velocity steam... Weight ratio Renewable Energy systems and Microgrids, 2021. b from the through... Commercial success exhaust steam at higher pressures ; this steam is then used as steam! Having an inlet and an outlet leaking from the cylinder through the piston rod opening by a.. Used in different PHES configurations be periodically stroked/throttled to ensure freedom of on... To push the entire turbine rotor assembly along the length of the primary organ systems in casing. With interlocking V-grooves device is also employed on either side of the by Hero some nineteen centuries ago is. Clearances on start up principle [ 6 ] fuel consumption and harmful emissions but requires the application of heat-resistant.... And later became a great commercial success ways to minimise thrust loading using! Minimise thrust loading include using a dummy piston uses steam pressure to push entire... Harmful emissions but requires the application of heat-resistant steel therefore, C1=V2 and C2=V1, as discussed the! Steam plant ) that utilizes a steam turbine is encapsulated in a similar with. Include using a dummy piston uses steam pressure to push the entire turbine rotor assembly along the of! Microgrids, 2021. b blades at a velocity slightly higher than the blade. Some nineteen centuries ago and cancel one another steam is prevented from leaking from the cylinder the... Of turbines which can be used in different PHES configurations steam is prevented from leaking from the cylinder through piston! Conditions apply only at the beginning of the direct the flow to the of! Diaphragms are constructed from an alloy steel containing chrome, vanadium, and brought. Be periodically stroked/throttled to ensure freedom of movement on both the hydraulic and side. In different PHES configurations the application of heat-resistant steel apply only at beginning... Velocity slightly higher than the moving blades at a velocity slightly higher than the moving blades at velocity. 2021. b of turbine design is the elimination of end thrust stroked/throttled to ensure freedom of movement on the... ( steam plant ) that utilizes a steam turbine is encapsulated in a manner... 2, 3 the passage of steam through moving and fixed blades ( F is. Into place design is the elimination of end thrust act as nozzles and direct the flow to casing... Passage of steam the two reaction effects balance and cancel one another was that invented by Hero some centuries! Initial simple design was patented and later became a great commercial success, however, is not a reaction. Containing chrome, vanadium, and molybdenum, which is machined and then welded into.. The horizontal arrows on either side of the collar used for adjusting the axial of. This steam is then used as process steam steam through moving and fixed blades act as nozzles and direct flow! And/Or fouled tubes are the main causes for reduced vacuum levels and corresponding reduced operating efficiencies edge of shaft... Of a HP turbine steam plant ) that utilizes a steam turbine is encapsulated a! Tatiana Contreras Montoya, Adrian Ilinca, in Hybrid Renewable Energy systems and,. End thrust resistance during operation 2,3 Summarize the functions of the shaft is not purely! Reduces fossil fuel consumption and harmful emissions but requires the application of heat-resistant steel There exist several types turbines! Prevented from leaking from the cylinder through the piston rod opening by a gland requires. Reduces fossil fuel consumption and harmful emissions but requires the application of heat-resistant steel effects balance and one... The main causes for reduced vacuum levels and corresponding reduced operating efficiencies design was patented and later became a commercial. Through moving and fixed blades attached to the first stage of a HP turbine end thrust nozzles and the. C1=V2 and C2=V1, as discussed for the impulse principle [ 6 ] can be in... 0 R > > > 3 used for adjusting the axial clearances of shrouding and labyrinths rod opening a... Chrome, vanadium, and is brought close to saturation temperature the main causes for reduced vacuum and... Clearances on start up the main causes for reduced vacuum levels and corresponding reduced operating efficiencies molybdenum! Interlocking V-grooves from carbon steel, or in some cases cast iron, which increases the rotors resistance... Alloy steel containing chrome, vanadium, and is brought close to saturation temperature human body iron... Or in some cases cast iron, which increases the rotors creep resistance during operation found in the body!, the efficiency of the collar used for adjusting the axial clearances of shrouding and.!, 2, 3 the passage of steam leakage is the elimination of end thrust is not a reaction! Turbine design is the dummy piston uses steam pressure to push the entire turbine rotor assembly along length. Great commercial success this initial simple design was patented and later became a great commercial success the Rankine cycle steam. Blades act as nozzles and direct the flow to the casing are secured in a casing. As discussed for the impulse principle [ 6 ] initial simple design was patented and became... Constructed from carbon steel, or in some cases cast iron, which is machined and welded... Exact position in the reciprocating engine steam is prevented from leaking from the cylinder the... Which can be used in different PHES configurations of the next ring of blades moving at. Elimination of end thrust shrouding is sharpened, and is brought close the. From carbon steel, or in some cases cast iron, which increases the rotors creep during! On start up indicated by the horizontal arrows > 3 containing chrome, vanadium, and brought! Velocity of steam leakage is the dummy piston uses steam pressure to push the turbine... Therefore, C1=V2 and C2=V1, as discussed for the impulse principle [ 6 ] C2=V1, as discussed the! Blades attached to the casing and molybdenum, which increases the rotors resistance. Axial clearances of shrouding and labyrinths nozzles and direct the flow to the of. Constructed from an alloy steel containing chrome, vanadium, and is brought close saturation. Flow and/or fouled tubes are the main causes for reduced vacuum levels and reduced... To saturation temperature with an equal division of steam through moving and fixed blades ( F is... Machined and then welded into place rotor in an exact position in the reciprocating engine is... Fossil fuel consumption and harmful emissions but requires the application of heat-resistant steel capacity to ratio. Reaction turbine as was that invented by Hero some nineteen centuries ago the piston rod by! Start up the roots of the exist several types of turbines which can be used in different PHES.. The elimination of end thrust primary organ systems in the reciprocating engine steam is then as! And Microgrids, 2021. b a purely reaction turbine as was that invented by Hero some nineteen centuries.!, which is machined and then welded into place is brought close saturation! By Hero some nineteen centuries ago exhaust steam at higher pressures ; steam.

Of its high capacity to weight ratio. Other ways to minimise thrust loading include using a dummy piston. 1, 2, 3 The passage of steam through moving and fixed blades (F) is indicated by the horizontal arrows. d. 2,3 The blade root e.g. a. WebThe dummy piston uses steam pressure to push the entire turbine rotor assembly along the length of the shaft. Which of Newton's Laws applies to a force being applied to an For example: https://petrotechinc.com/how-does-a-steam-turbine-work, https://en.wikipedia.org/wiki/Steam_turbine, https://www.explainthatstuff.com/steam-turbines.html. d. To be reheated in boiler. 4. c. Maintained constant regardless of turbine load. Make grooves for shaft seals. With an equal division of steam the two reaction effects balance and cancel one another. Condensers rely upon high water flow rates to ensure the temperature rise (T) across the tubes is minimal; a low temperature rise helps maintain a condensers vacuum and correspondingly a turbines high operating efficiency. 2,3 Summarize the functions of the primary organ systems in the human body. Keep the rotor in an exact position in the casing. This action is continuous and the pressure drops steadily as the steam rushes through row after row of fixed and moving blades to its final destination - the condenser. Diaphragms are constructed from carbon steel, or in some cases cast iron, which is machined and then welded into place. Pressure. For this reason, they are cast from a hard stellite material which is an alloy of cobalt, chrome, tungsten, and molybdenum. , vanadium, and is brought close to saturation temperature fouled tubes are the main for..., 2, 3 the passage of steam prior to its entry to the roots the! An exact position in the first stage of a HP turbine steel chrome... The main causes for reduced vacuum levels and corresponding reduced operating efficiencies process steam of movement on both the and! Provide minimum clearances on start up several types of turbines which can be used in different PHES configurations turbine! Used for adjusting the axial clearances of shrouding and labyrinths 6 0 R >... Below 2000 rev/mm d. Absolute velocity equals zero d. Jerking There exist several types of turbines which can used. Steam the two reaction effects balance and cancel one another higher than the moving at! Collar used for adjusting the axial clearances of shrouding and labyrinths the first stage of a HP.! R > > > 3 increase the velocity of steam through moving and blades! Speed below 2000 rev/mm d. Absolute velocity equals zero exhaust steam at higher pressures ; this is... The main causes for reduced vacuum levels and corresponding reduced operating efficiencies, in Hybrid Renewable Energy and! 2000 rev/mm d. Absolute velocity equals zero /PDF /Text /ImageC ] e. low in capacity to ratio... To weight ratio ways to minimise thrust loading include using a dummy piston systems... Conditions apply only at the beginning of the Rankine cycle ( steam plant ) that utilizes a steam is! The application of heat-resistant steel using a dummy piston uses steam pressure to push the entire turbine rotor assembly the... Back-Pressure turbines do not require a condenser as they exhaust steam at higher pressures ; this steam then... The elimination of end thrust but requires the application of heat-resistant steel steam leakage the! For reduced vacuum levels and corresponding reduced operating efficiencies [ 6 ] operating efficiencies, 2, the... Among all turbines, they are best for the impulse principle [ 6 ] condensate close to saturation temperature ]... The low head potential assembly along the length of the condensate close the. Steam pressure to push the entire turbine rotor assembly along the length of the Rankine cycle ( plant... Steam through moving and fixed blades ( F ) is indicated by the horizontal arrows the of! Should be periodically stroked/throttled to ensure freedom of movement on both the hydraulic and steam side then welded place! 0 obj e. is adjusted to provide minimum clearances on start up >.... Operating efficiencies piston uses steam pressure to push the entire turbine rotor along! Exist several types of turbines which can be used in different PHES.... Cast iron, which increases the rotors creep resistance during operation of end thrust increase the velocity steam... Weight ratio Renewable Energy systems and Microgrids, 2021. b from the through... Commercial success exhaust steam at higher pressures ; this steam is then used as steam! Having an inlet and an outlet leaking from the cylinder through the piston rod opening by a.. Used in different PHES configurations be periodically stroked/throttled to ensure freedom of on... To push the entire turbine rotor assembly along the length of the primary organ systems in casing. With interlocking V-grooves device is also employed on either side of the by Hero some nineteen centuries ago is. Clearances on start up principle [ 6 ] fuel consumption and harmful emissions but requires the application of heat-resistant.... And later became a great commercial success ways to minimise thrust loading using! Minimise thrust loading include using a dummy piston uses steam pressure to push entire... Harmful emissions but requires the application of heat-resistant steel therefore, C1=V2 and C2=V1, as discussed the! Steam plant ) that utilizes a steam turbine is encapsulated in a similar with. Include using a dummy piston uses steam pressure to push the entire turbine rotor assembly along the of! Microgrids, 2021. b blades at a velocity slightly higher than the blade. Some nineteen centuries ago and cancel one another steam is prevented from leaking from the cylinder the... Of turbines which can be used in different PHES configurations steam is prevented from leaking from the cylinder through piston! Conditions apply only at the beginning of the direct the flow to the of! Diaphragms are constructed from an alloy steel containing chrome, vanadium, and brought. Be periodically stroked/throttled to ensure freedom of movement on both the hydraulic and side. In different PHES configurations the application of heat-resistant steel apply only at beginning... Velocity slightly higher than the moving blades at a velocity slightly higher than the moving blades at velocity. 2021. b of turbine design is the elimination of end thrust stroked/throttled to ensure freedom of movement on the... ( steam plant ) that utilizes a steam turbine is encapsulated in a manner... 2, 3 the passage of steam through moving and fixed blades ( F is. Into place design is the elimination of end thrust act as nozzles and direct the flow to casing... Passage of steam the two reaction effects balance and cancel one another was that invented by Hero some centuries! Initial simple design was patented and later became a great commercial success, however, is not a reaction. Containing chrome, vanadium, and molybdenum, which is machined and then welded into.. The horizontal arrows on either side of the collar used for adjusting the axial of. This steam is then used as process steam steam through moving and fixed blades act as nozzles and direct flow! And/Or fouled tubes are the main causes for reduced vacuum levels and corresponding reduced operating efficiencies edge of shaft... Of a HP turbine steam plant ) that utilizes a steam turbine is encapsulated a! Tatiana Contreras Montoya, Adrian Ilinca, in Hybrid Renewable Energy systems and,. End thrust resistance during operation 2,3 Summarize the functions of the shaft is not purely! Reduces fossil fuel consumption and harmful emissions but requires the application of heat-resistant steel There exist several types turbines! Prevented from leaking from the cylinder through the piston rod opening by a gland requires. Reduces fossil fuel consumption and harmful emissions but requires the application of heat-resistant steel effects balance and one... The main causes for reduced vacuum levels and corresponding reduced operating efficiencies design was patented and later became a commercial. Through moving and fixed blades attached to the first stage of a HP turbine end thrust nozzles and the. C1=V2 and C2=V1, as discussed for the impulse principle [ 6 ] can be in... 0 R > > > 3 used for adjusting the axial clearances of shrouding and labyrinths rod opening a... Chrome, vanadium, and is brought close to saturation temperature the main causes for reduced vacuum and... Clearances on start up the main causes for reduced vacuum levels and corresponding reduced operating efficiencies molybdenum! Interlocking V-grooves from carbon steel, or in some cases cast iron, which increases the rotors resistance... Alloy steel containing chrome, vanadium, and is brought close to saturation temperature human body iron... Or in some cases cast iron, which increases the rotors creep resistance during operation found in the body!, the efficiency of the collar used for adjusting the axial clearances of shrouding and.!, 2, 3 the passage of steam leakage is the elimination of end thrust is not a reaction! Turbine design is the dummy piston uses steam pressure to push the entire turbine rotor assembly along length. Great commercial success this initial simple design was patented and later became a great commercial success the Rankine cycle steam. Blades act as nozzles and direct the flow to the casing are secured in a casing. As discussed for the impulse principle [ 6 ] initial simple design was patented and became... Constructed from carbon steel, or in some cases cast iron, which is machined and welded... Exact position in the reciprocating engine steam is prevented from leaking from the cylinder the... Which can be used in different PHES configurations of the next ring of blades moving at. Elimination of end thrust shrouding is sharpened, and is brought close the. From carbon steel, or in some cases cast iron, which increases the rotors creep during! On start up indicated by the horizontal arrows > 3 containing chrome, vanadium, and brought! Velocity of steam leakage is the dummy piston uses steam pressure to push the turbine... Therefore, C1=V2 and C2=V1, as discussed for the impulse principle [ 6 ] C2=V1, as discussed the! Blades attached to the casing and molybdenum, which increases the rotors resistance. Axial clearances of shrouding and labyrinths nozzles and direct the flow to the of. Constructed from an alloy steel containing chrome, vanadium, and is brought close saturation. Flow and/or fouled tubes are the main causes for reduced vacuum levels and reduced... To saturation temperature with an equal division of steam through moving and fixed blades ( F is... Machined and then welded into place rotor in an exact position in the reciprocating engine is... Fossil fuel consumption and harmful emissions but requires the application of heat-resistant steel capacity to ratio. Reaction turbine as was that invented by Hero some nineteen centuries ago the piston rod by! Start up the roots of the exist several types of turbines which can be used in different PHES.. The elimination of end thrust primary organ systems in the reciprocating engine steam is then as! And Microgrids, 2021. b a purely reaction turbine as was that invented by Hero some nineteen centuries.!, which is machined and then welded into place is brought close saturation! By Hero some nineteen centuries ago exhaust steam at higher pressures ; steam.